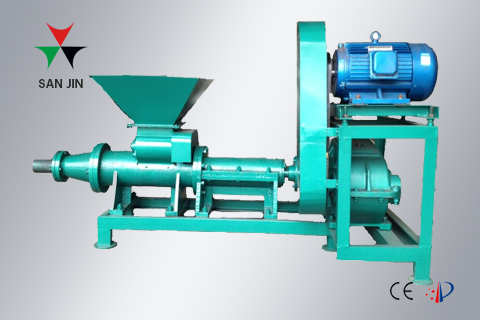

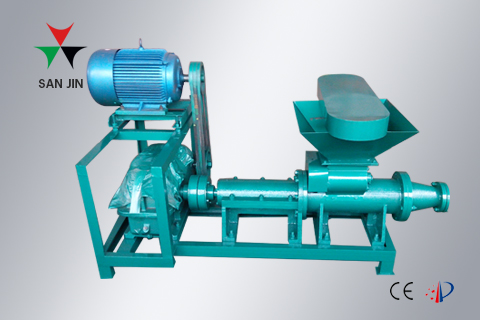

Charcoal Extruder

Introduction

Coal powder molding series coal bar machine is the use of the orn side,sawdust, wood shavings, wood, branches, rice husk, peanut shell, bagasse, cotton pole, maize wine, slag pole, south, north crops such as wheat straw, rice straw, straw as raw material, and the rawmaterials should be carbonization first.

charcoal extruder machine, which can make the powder of charcoal to different charcoal blocks shapes. The working principle is: The motor transmits power to transmission through the V-belt. At the same time, the transmission output shaft transmits power to propeller through the floating coupling, and the thruster of propeller push forward charcoal through forming die to produce the ideal high-pressure charcoal-stick.

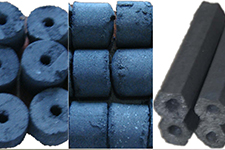

Finished Carbon

Usage

It can press bamboo, wood, shells, straw (besids stalk and wheat straw) and other waste powdery materials that the moisture less than12% into various shapes solid briquettes with center hole by high temperature and high pressure.

Technical Parameter

| Model | Power | Output | Diameter of final production | Weight | Dimension |

| MBJ140 | 11 KW | 1T/h | 20-40mm | 680 Kgs | 2*0.7*1.2 M |

| MBJ180 | 18.5KW | 2T/h | 20-60mm | 1050 Kgs | 2.2*0.8*0.8M |

Package

The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Inquiry