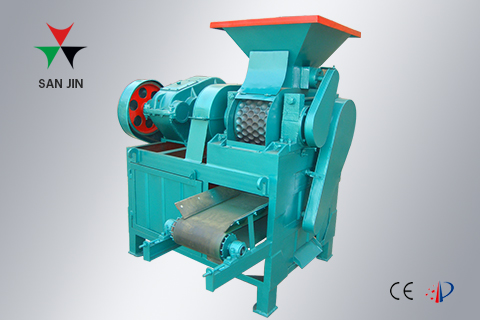

Coal Ball Press Machine

Introduction

Charcoal ball pressure machine means we use briquette machine who has two big rollers to press fine charcoal powder into small ball shape briquettes. The rollers of charcoal ball pressure machine are made of 65Mn, which makes rollers have long service time. Raw material of charcoal ball pressure machine can be coal powder. charcoal powder, iron powder, carbon black coal powder, coking coal powder, carbon powder, gypsum powder, ore powder, refractory powder, fertilizer powder, coke powder, limestone powder, carbon powder, carbon black powder, coking coal powder, etc. The final briquettes shapes can be egg shape, round shape, oval shape, square shape, pillow shape, or any other shapes according to your requirements.(charcoal ball pressure machine)

The Feature

- 01

In order to ensure the good quality and mechanical strength of the final product, special care should be taken to ensure that the granule size fed to the machine is maintained below 3mm,preferable in the range of 30~40% small than1~2mm, with no more than 10% over 2mm.

- 02

The moisture content of the mixture has also a critical effect on the quality of the final product, so it should be kept in the range of 8~20%.

- 03

Raw material of coal industry(coal powedr, coke, coal sludge, etc)need to make coal briquette, using in industrial boilers and civilian boiler.

Work Principle

- Motive power will transmit to two rollers through the reducer synchronously and make them rotate oppositely. Materials enter into ball mode naturally, with rollers rotation, pressure of materials bearing becomes larger. When arriving at two rollers contact point, materials bearing pressure reaches peak. Under the tremendous pressure, materials become ball shape from powder shape.

Technical Parameter

| Model | SJ-4 | SJ-6 | SJ-8 | SJ-10 | SJ-15 | SJ-20 | SJ-30 | SJ-40 | |

| Production | Hour | 3-4T/h | 6T/h | 8T/h | 10T/h | 15T/h | 20T/h | 30T/h | 40T/h |

| Roll Width | 250mm | 240mm | 220mm | 300mm | 336mm | 400/500mm | 500mm | 700mm | |

| Roll Diameter | 360mm | 400mm | 450mm | 500mm | 650mm | 750mm | 850mm | 1000mm | |

| Power | 7.5-11KW | 11-15KW | 15-18.5KW | 18.5-30KW | 22-45KW | 30-55KW | 55-90KW | 90-110KW | |

Package

The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Inquiry