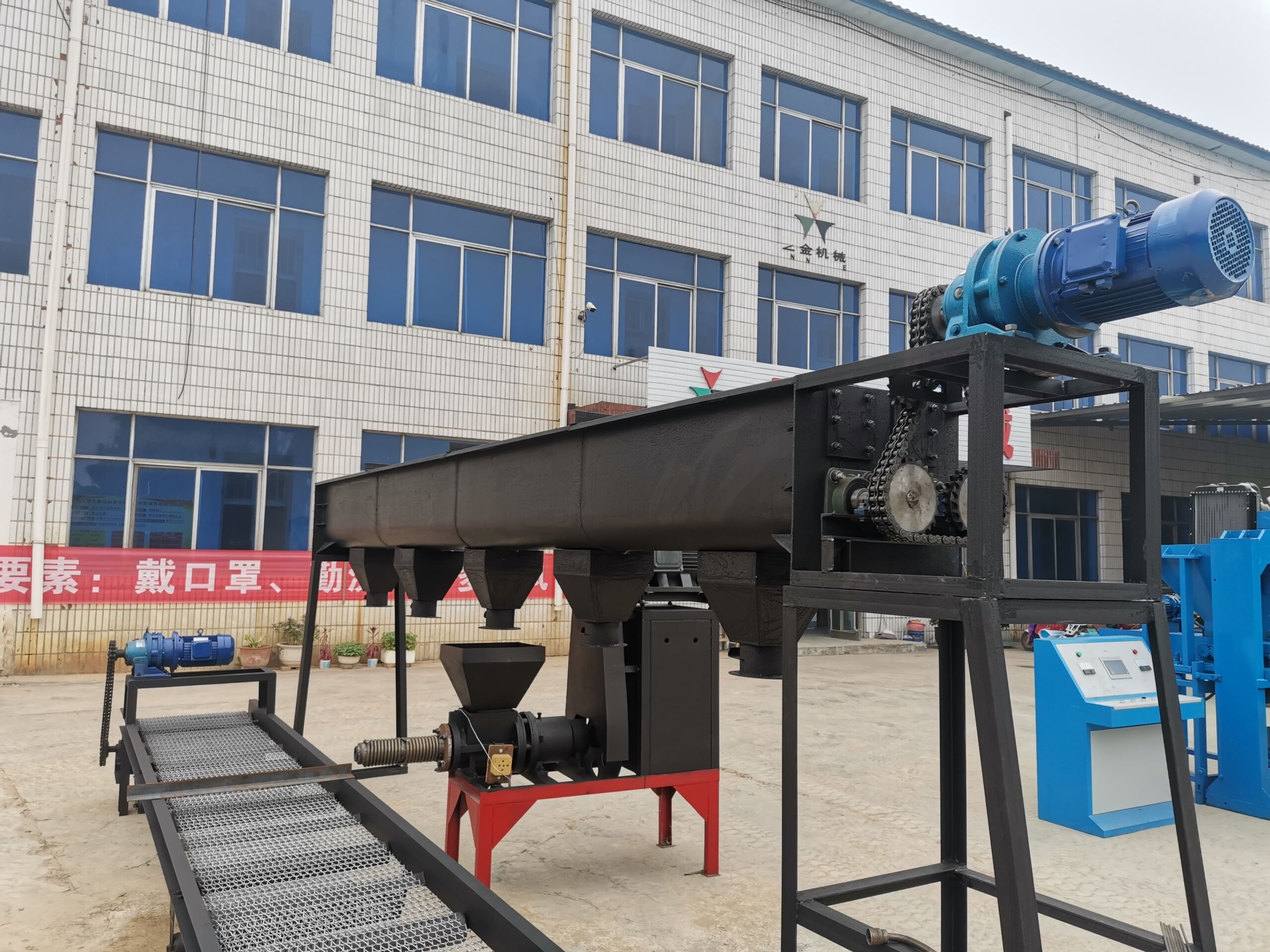

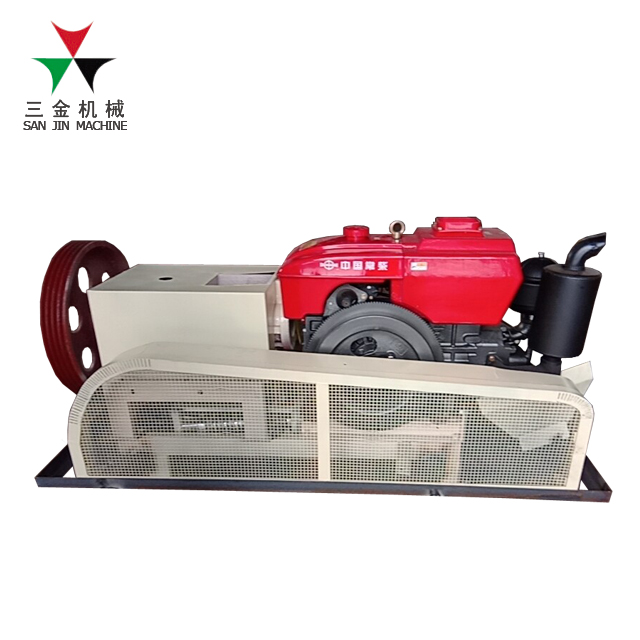

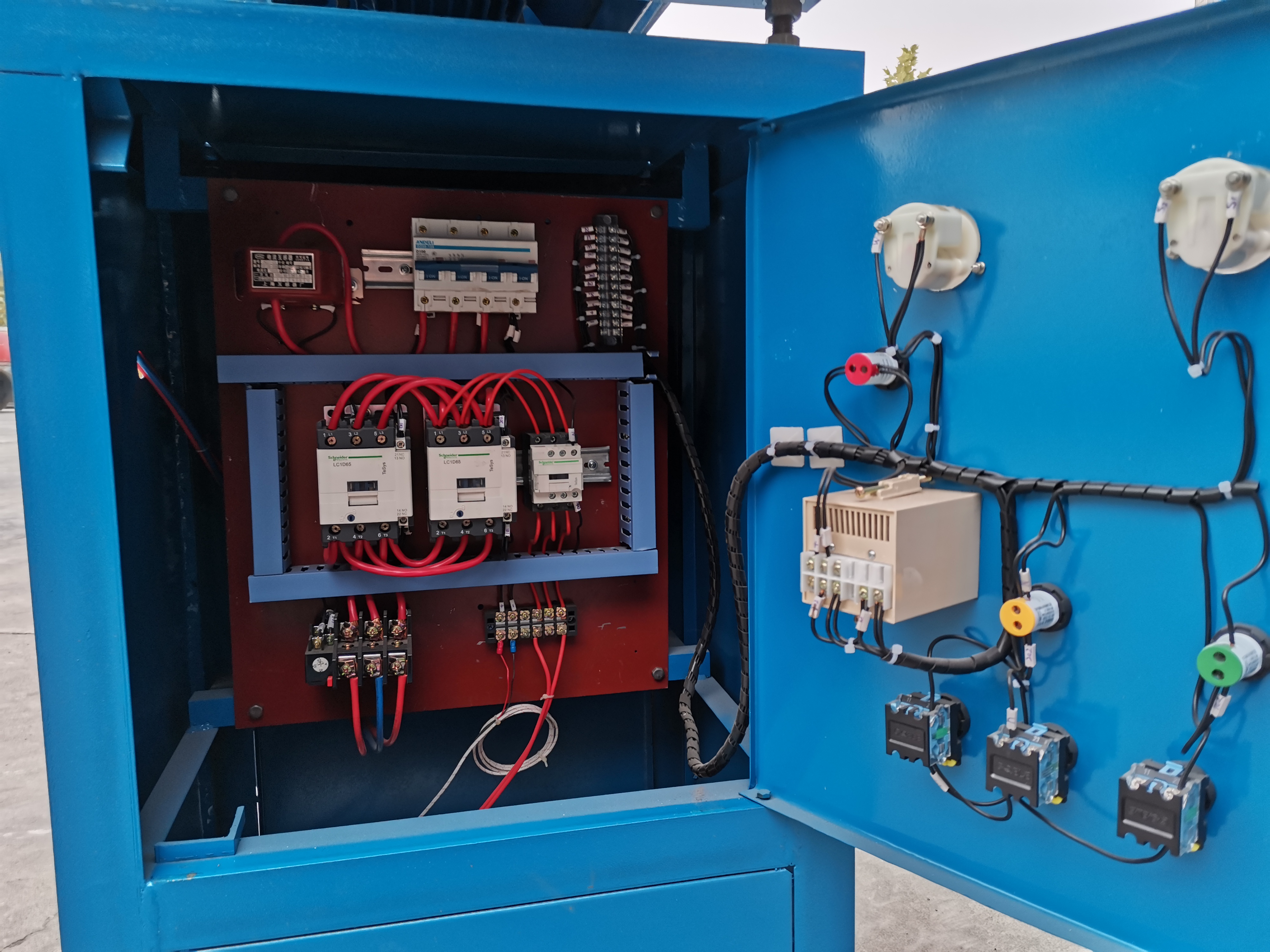

Wood Sawdust Charcoal Briquette Making Machine

Almost any biomass can be briquetted. Briquetting plants set so far are using Saw Dust, Bamboo dust, Bagasse, Cotton Stalk, Coffee husk, Groundnut Shell, Mustard Husk/Stalk, Pine Needles, Rice Husk, Sugar Mill Waste, Jute waste, Coir pith and other wastes & residues like Castor Shell, Red Gram Stalk, Tobacco stem, Tea Waste, Sander Dust, Tree Bark, Wild Grasses & Shrubs and Sander dust etc. can be also be briquetted individually or in combination without using any binder.

Briquettes are made by grinding Biomass and sawdust into a homogeneous pulp and forming this into a briquette under very high pressure. High pressure & pressing releases one of the natural components of wood – lignin which has the property of becoming liquid at high pressure (temperature) and, as it subsequently cools, it binds the wood together in its new form Briquettes.

The final bio-fuel briquette is made by the advanced biomass briquetting machine. This bio-fuel briquette is 45-80mm in diameter, occurs in the hollow quadrangular or hexagonal cylinder or hollow hexagonal with a 15-20mm hole through the body.

As the need of pollution free environment, the product has a large scope of marketing. The briquettes can be used as a substitute of any fuel in following fields :

Boilers : It can be used in the boilers of Paper Mills, Sugar Mills, Dyeing houses, leather, lamination industries, Vanaspati units, Food Processing Units, Oil Extraction Units, Solvent Extraction Plant and many other plants and industries..

Furnace & Foundries : It can be used for metal heating & melting (where melting point is less than 1000d/cel.)

Brick Kilns : It is the total, substitute of steam coal.

Residential & Commercial Heating : For winter heating in Cold areas and Hotels, Canteens, Cafeterias and house hold kitchen appliances etc.