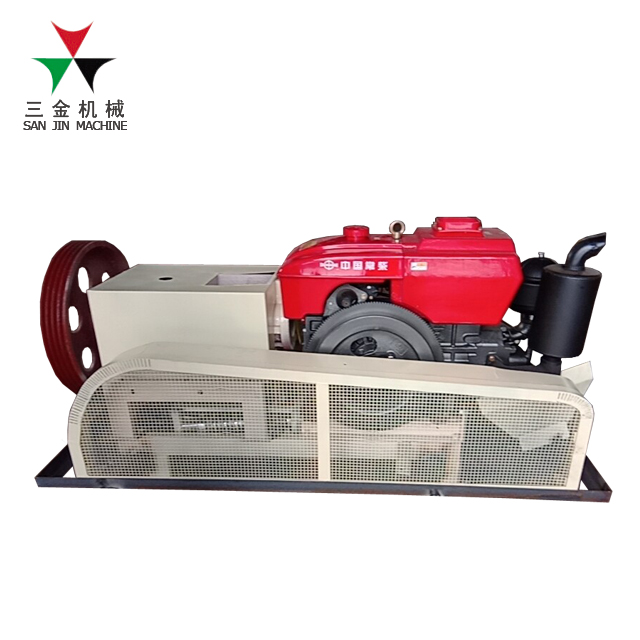

Wood Sawdust Charcoal Briquette Making Compress Machine inTurkey

Wood Sawdust Charcoal Briquette Making Compress Machine inTurkey

1. No binder or noxious chemical need to use.

2. The humidity of the raw materials is controlled in 8-12%.

3. Using the advanced Hot air drying system with the perfect performance.

4. After the processing of high temperature, purification, smoke removing, the carbonizing equipment transforms the semi-finished bio-fuel briquette intoa smoke-free, tasteless, non-toxic cleaning carbon

Wood Sawdust Charcoal Briquette Making Compress Machine in Turkey

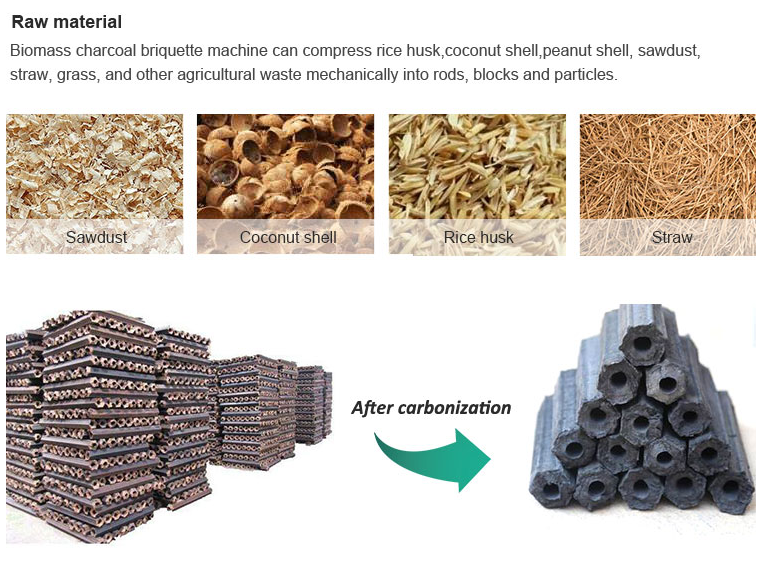

biomass briquette machine uses a large screw to grind, compress and extrude the biomass into briquettes. The natural lignin content in biomass is liberated with wood fiber under high pressure and temperature. In the briquetting process lignin serves as the glue and combines the particles of wood together, thus binding, compressing the biomass to form into various moulds of high density briquette, such as hexagonal, quadrangular, square, etc. During this process, non-binder needs to be used.