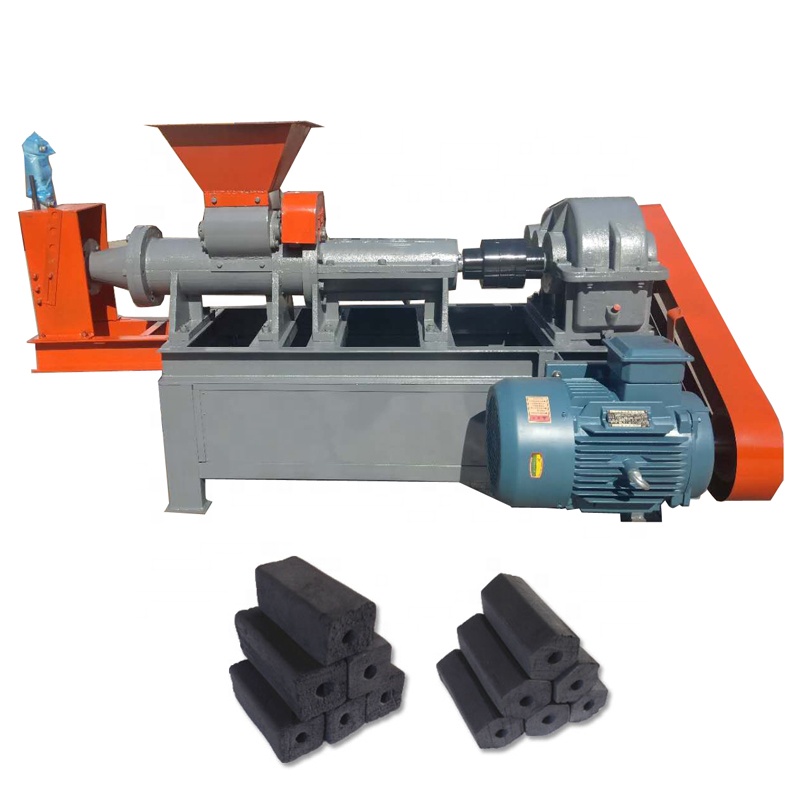

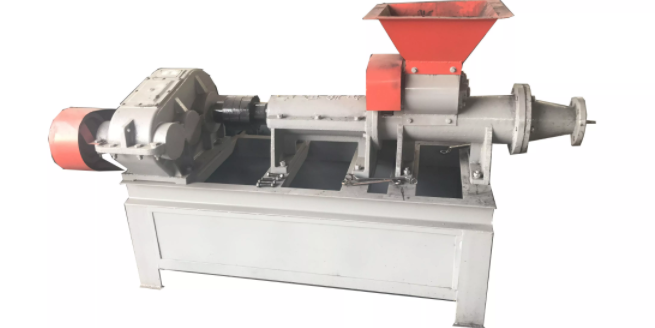

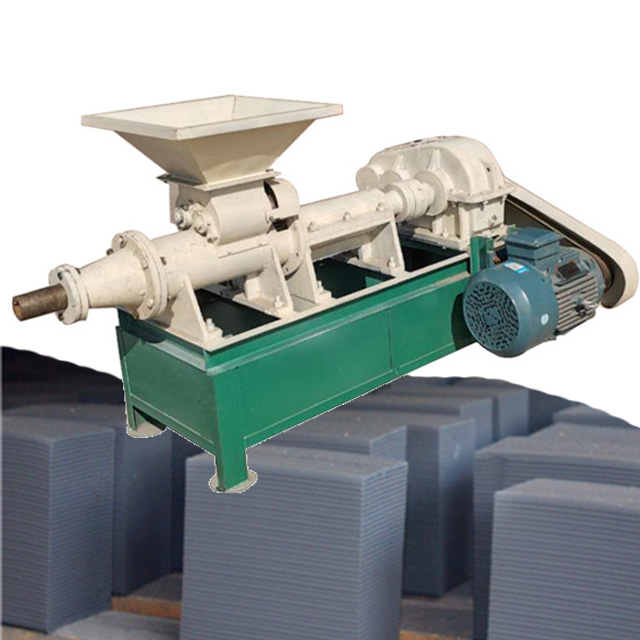

sawdust charcoal briquette press machine

sawdust charcoal briquette press machine

This equipment uses sawdust, shavings, wood scraps, branches, rice husks, peanut husks, corn stalks, wheat straw, straw and other crops as raw materials. After extrusion, it is carbonized in a carbonization furnace to become finished charcoal . It is also possible to directly use pulverized coal as raw material and extrude into coal sticks.

Contact US

Get Price

Share:

Content

sawdust charcoal briquette press machine

|

Model

|

MBJ-140

|

MBJ-180

|

|

Voltage

|

380V/50HZ

|

380V/50HZ

|

|

power

|

11KW

|

22KW

|

|

Capacity

|

1-2T/H

|

2-3T/H

|

|

Diameter

|

1900*1100*1170MM

|

2210*1370*1400MM

|

Machine structure characteristics

1. Large feeding screw lead, fast feeding, small advancing screw lead, saving power. 2. The shaft seat and the cylinder are rigidly connected, with high concentricity, anti-reverse thrust, and the machine is stable. 3. V-belt transmission, stable operation, low noise, and its overload protection function.

The cutting device can also be added according to the needs, and the cutting length can be set, so that the length of the finished product is uniform. Easy to pack.

Use and maintenance of the machine

1. Before starting the machine, check whether the rotating parts are flexible and whether there is any abnormal noise. The empty machine can be put into production after 2 to 3 minutes. 2. The raw material must be processed, the maximum particle size is less than 3mm 3. If the feeding port is blocked, use wooden or bamboo to clear it, and never use metal rods. 4. The bearings of the rotating parts of the machine should be filled with lubricating oil regularly, and the temperature of the bearing parts should not exceed 60 degrees. 5. Stop unloading before stopping the machine, stop the machine after the material in the cylinder is emptied, disassemble the machine head, clean it and reinstall it for next use.

Inquiry

More Charcoal Extruder Machine