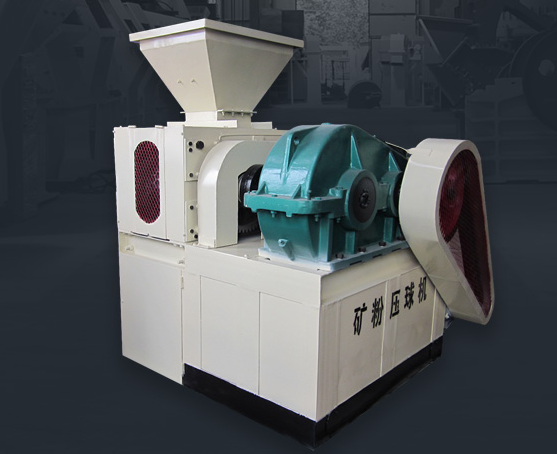

roller press machine for charcoal powder ball briquetting

roller press machine for charcoal powder ball briquetting

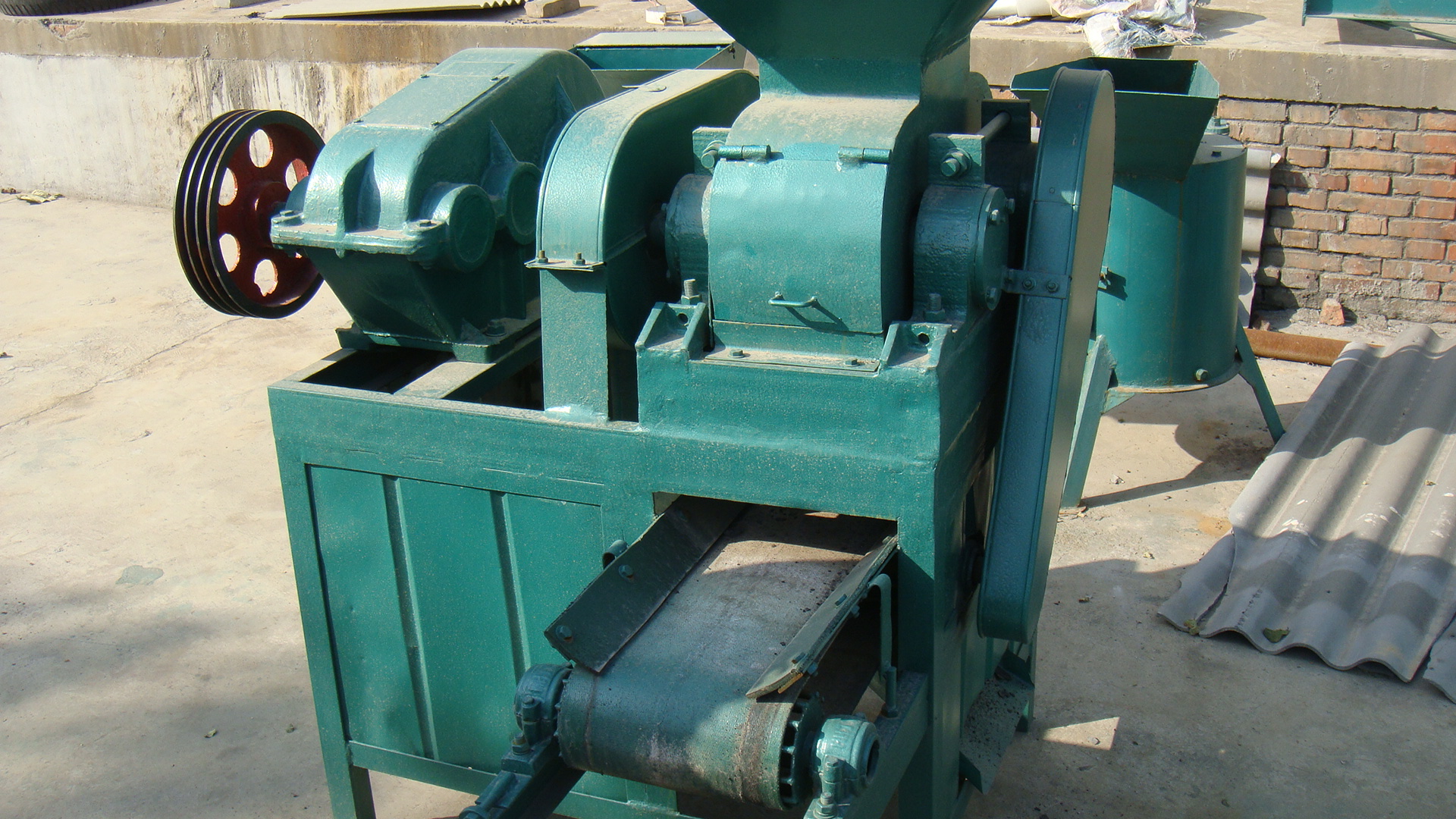

Due to the constant torque of the electromagnetic variable-speed motor, when the pressing amount of the spiral feeder machine is the same with the needed material amount by the main engine, stable material supplying pressure can be ensured to stabilize the quality of the pellet. If the material supplying amount is high, the electricity of the feeder machine will be overload; if the material supplying amount is low, the materials will not be able to be pressed to pellet. For this reason, skillful operation technique is an important condition to ensure the normal work of ball press machine.

Briquette Machine is equipped with self-protective device. The hydraulic protective device can inject the high pressure oil into the hydraulic cylinder with the hydraulic pump and make the piston produce axial displacement. The font joint of the piston rod is pressed onto the bearing pedestal to satisfy the production pressure requirement. When there are too many materials between the two rollers or metal block goes into the rollers, the hydraulic cylinder piston rod will pressed, and the hydraulic pump will stop, and the energy accumulator will have buffer action on the pressure change. The overflow valve will start for oil return and the piston rod will have displacement to increase the gap between the two rollers, so that the hard materials will go through the rollers, and then the system pressure will resume to normal, this design can protect the roller from being damaged. According to the requirement for the press density, this machine can be adjusted in pressure, so that the production process is mobile and flexible.