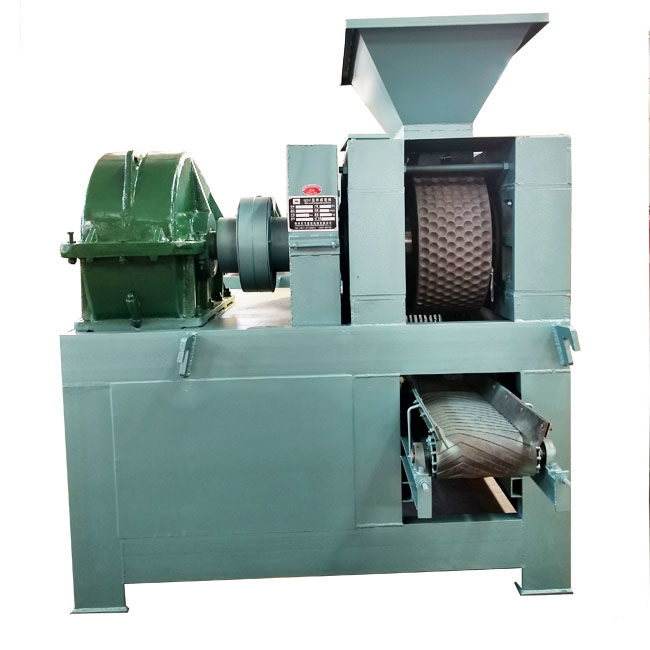

Pulverized coal press Charcoal dust briquetting ball machine

Pulverized coal press Charcoal dust briquetting ball machine

Roller briquette press machine

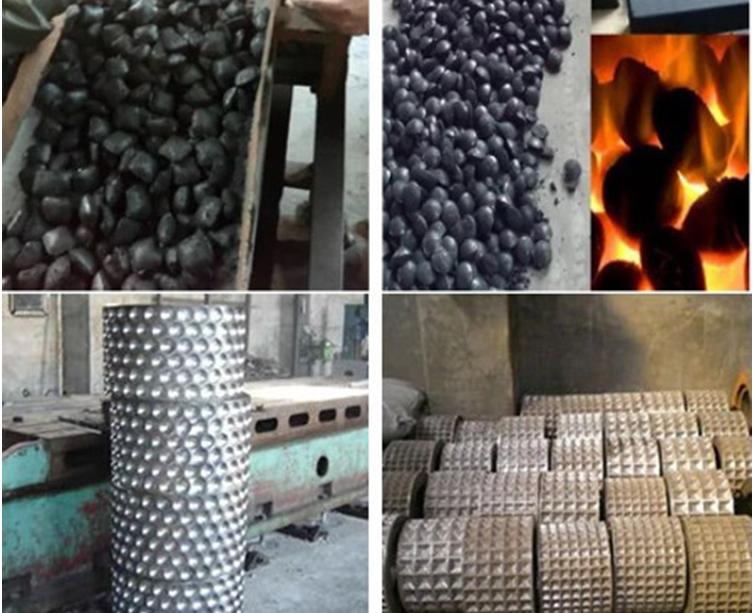

Briquette shape: round, pillow, square, etc

Briquette size: 10-80 mm (in diameter)

Capacity per set: 0.3-12 t/h

The roller briquette press machine makes a continuous charcoal briquette process with large capacity. With one briquetter, the capacity can even to 30 t/h. The briquette is also easy to be packed with packing machines

Pulverized coal press Charcoal dust briquetting ball machine

In-put materials:

1.Raw material size should be smaller than 5mm;

2.The best moisture for briquetting is 10-15%;

3.Binder: add different binders according to your raw material and final briquettes requirements;

4.Raw material of charcoal briquette press machine: charcoal powder, coal powder, coke powder, carbon powder, carbon black powder, fine sawdust powder, mineral powder, ore powder, iron powder, refractory powder, etc.

Working principle:

Ball pressure machine through reducer simultaneously transmitted the power to two pressure rollers and made them rotated in opposite directions. In two pressure rollers rotation, materials naturally enter into the ball molds on pressure roller and materials pressure vary from small to large with the rotation of the pressure roller. When the material is rotated to two rollers line contact points, materials pressure has reached a peak. Under enormous pressure, the powder materials are suppressed into finished ball.