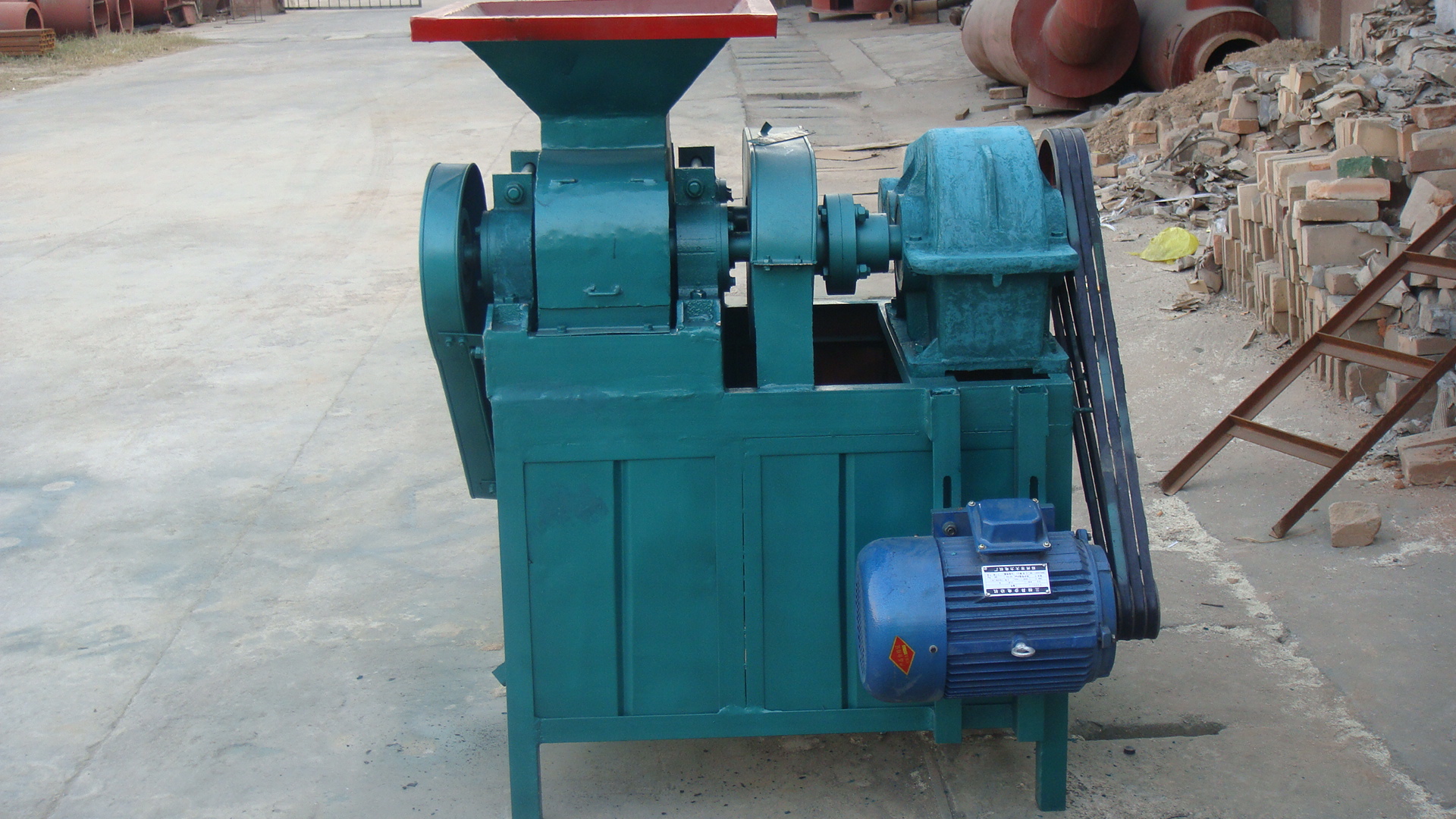

Professional pressing pressure ball machine briquetting machine

Professional pressing pressure ball machine briquetting machine

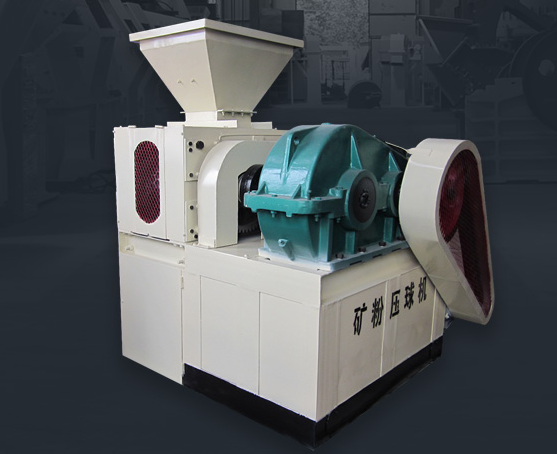

Our briquette machine are rollers pressing type. This type of briquette presses can apply higher pressures and thus produce higher density briquettes . These briquettes can be designed of oval shape, egg shape, pillow shape, square shape etc. This machine is widely used in coal industry and metallurgy industry.

Professional pressing pressure ball machine briquetting machine

A: Coal/coke/charcoal powder.

B: Metal powder: Iron powder, magnesium oxide powder, copper powder, chromium ore, lead, zinc scrap, bauxite, nonferrous metal powder, silicon manganese alloy powder etc.

C. Mineral powder: aluminum powder, toner, gypsum, sludge, desulphurization gypsum powder etc

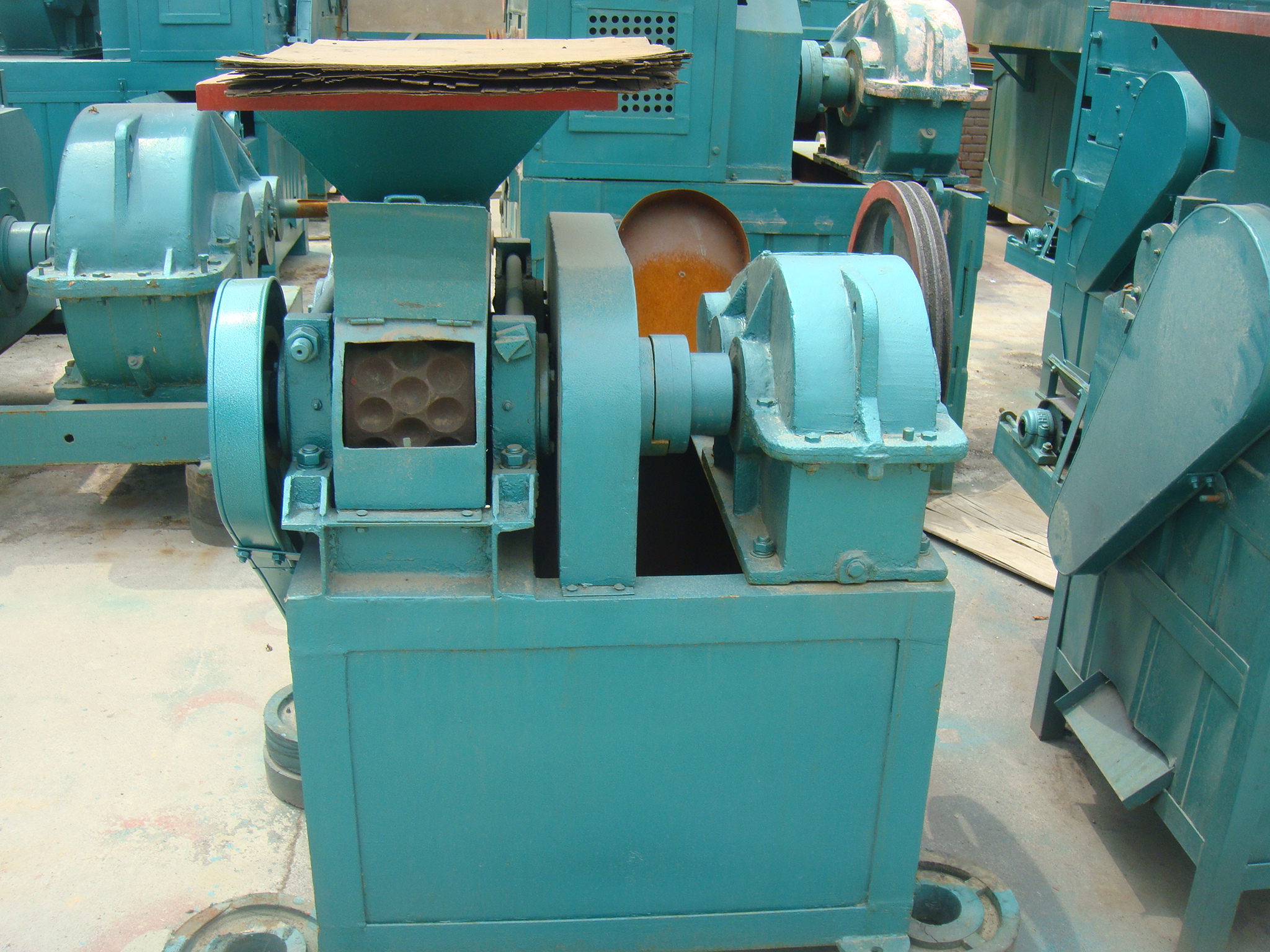

3. The working principles of the Professional pressing pressure ball machine rice husk coal dust briquette roller press charcoal briquetting machine

This series of Briquette Ball Press will pass the power on to the two pressure roller through the reducer.The two sides and roll rotation, in both the rotating roll,Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger, When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials become a finished product from the powder ball.