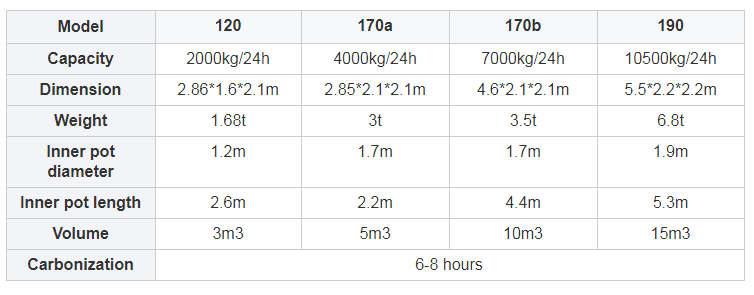

Non-smoke Charcoal Biochar Carbonization Furnace

This equipment organically combines the principle of gasification continuous carbonization and drum heating principle to realize a new process of smokeless carbonization. The main raw materials of continuous carbonization furnace are rice husk, straw, bagasse, palm shreds, bark and other plant wastes containing lignin. The carbonization efficiency is high, continuous production is possible, and smoke-free environmental protection is important for environmental protection Contribution.

Non-smoke Charcoal Biochar Carbonization Furnace

Carbonization charcoal stove/oven/kiln/furnace was developed by our factory latest modular air coking furnace, more Efficient than old type carbonized furnace, greatly shorten the production cycle, improve the efficiency of charcoal production, is an ideal equipment of large and medium scale charcoal production of charcoal. It uses a unique storage chamber structure, make full use of the flue gas produced by carbonization. In addition to their use of the stove, achieve energy conservation and environmental protection requirements.Energy-saving air coking furnace: simple and convenient, need not power and mobile production.It is an ideal equipment of family scale production.

It adopts the advanced carbonized technology heat flow,carbonized rate increased significantly,The carbonized rate is about 80%, up by 99%.And the operation is very convenient, good safety,high production efficiency,can save a lot of energy, good environmental protection performance.Shunt can also dry burning boiler flue gas and so on.Truly the charcoal,gas and oil range of equipment.Is currently the world’s most advanced carbonization furnace.