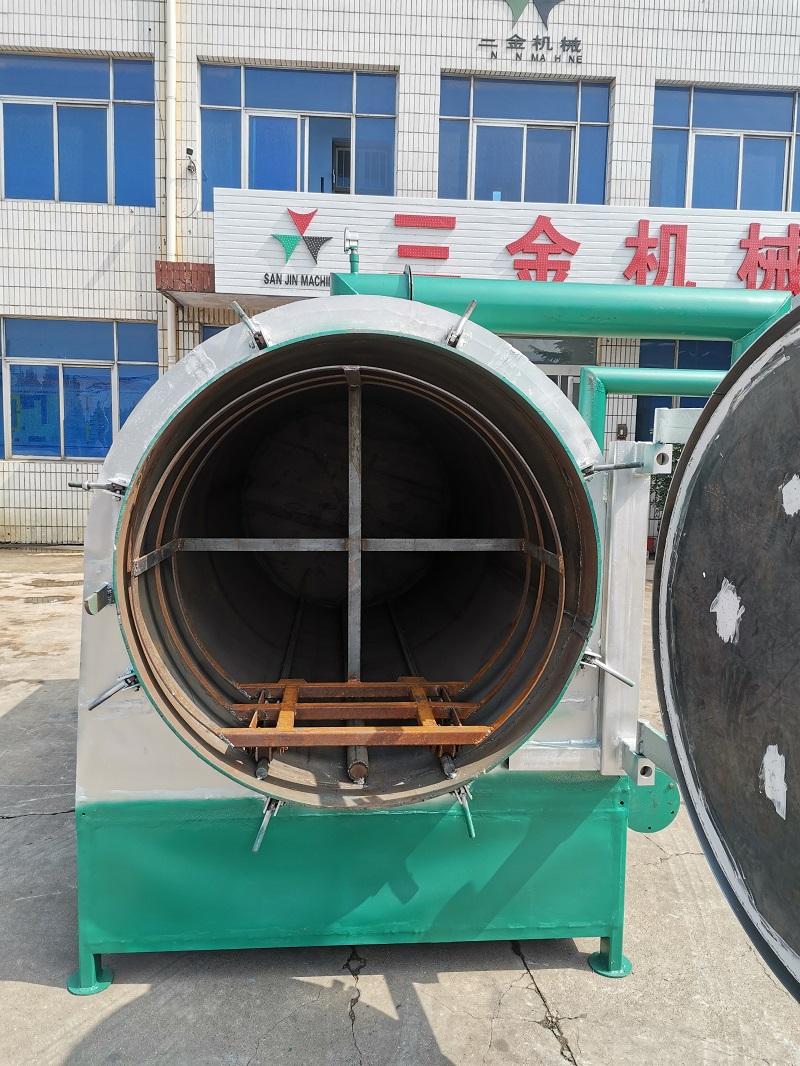

Horizontal industrial horizontal airflow wood charcoal carbonization furnace china sawdust charcoal making machine

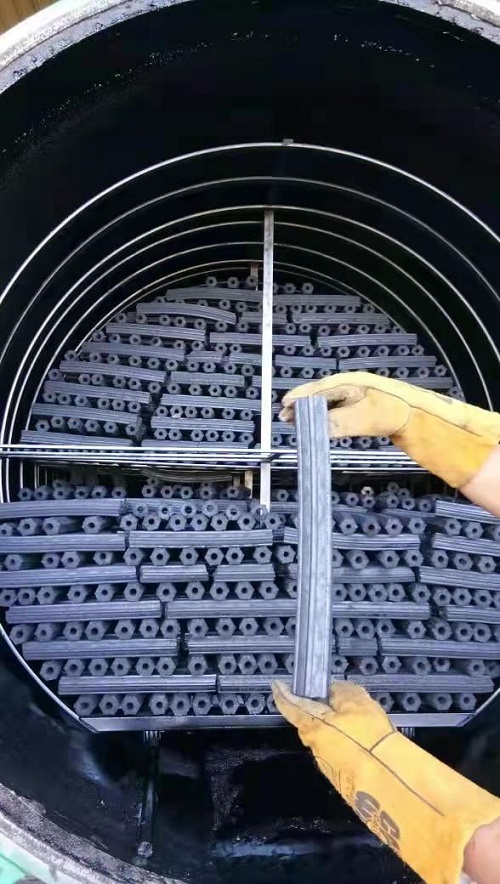

At present, there are three types of carbonization furnaces, common type (can only be used to produce charcoal, not to collect gas); wood carbonization equipment (used to carbonize branches, wood blocks, coconut shell blocks, scrap pieces in furniture factories, etc.) This equipment can be configured The gas recovered by the gasification furnace device can be turned into fuel gas for the carbonization furnace’s own use or other); the new horizontal environmentally friendly carbonization furnace has the effect of one machine and two purposes, and the materials can also be directly carbonized, or can be carbonized after rods.

Horizontal industrial horizontal airflow wood charcoal carbonization furnace china sawdust charcoal making machine

Advantages of horizontal jet carbonization furnace

1.The carbonization furnace adopts a horizontal manufacturing process. The carbonization furnace workers have a total of 30% structure, and there are light insulation materials in the interlayer, which can always keep the temperature in the furnace without dissipating

2. The furnace door is sealed with a boiler cover and filled with thick rock wool, no air will enter, and the carbon output rate is much higher than that of a conventional carbonization furnace

3. The reason why it is called an environmentally friendly carbonization furnace is because the wood rods will produce a lot of light yellow combustible gas during the carbonization process. These gases can divert the combustible gas to the combustion zone of the carbonization furnace through the pipes of the carbonization furnace for secondary heating. , More environmentally friendly and fuel-efficient

4. The excess gas from the carbonization furnace can be used to dry sawdust or burn the boiler

5. The carbonization furnace finishes the charcoal burning and the cooling time is shorter, and the space between the interlayer is used to cool the carbonization furnace with water, which is faster and more convenient.

6. The environmental protection horizontal airflow carbonization furnace can match the corresponding track and kiln car according to the needs of customers.Customers buying this kind of carbonization furnace have achieved simple operation, low labor intensity, convenient charging and discharging, and the cooling time is greatly reduced. The output of the carbonization furnace can be greatly improved.