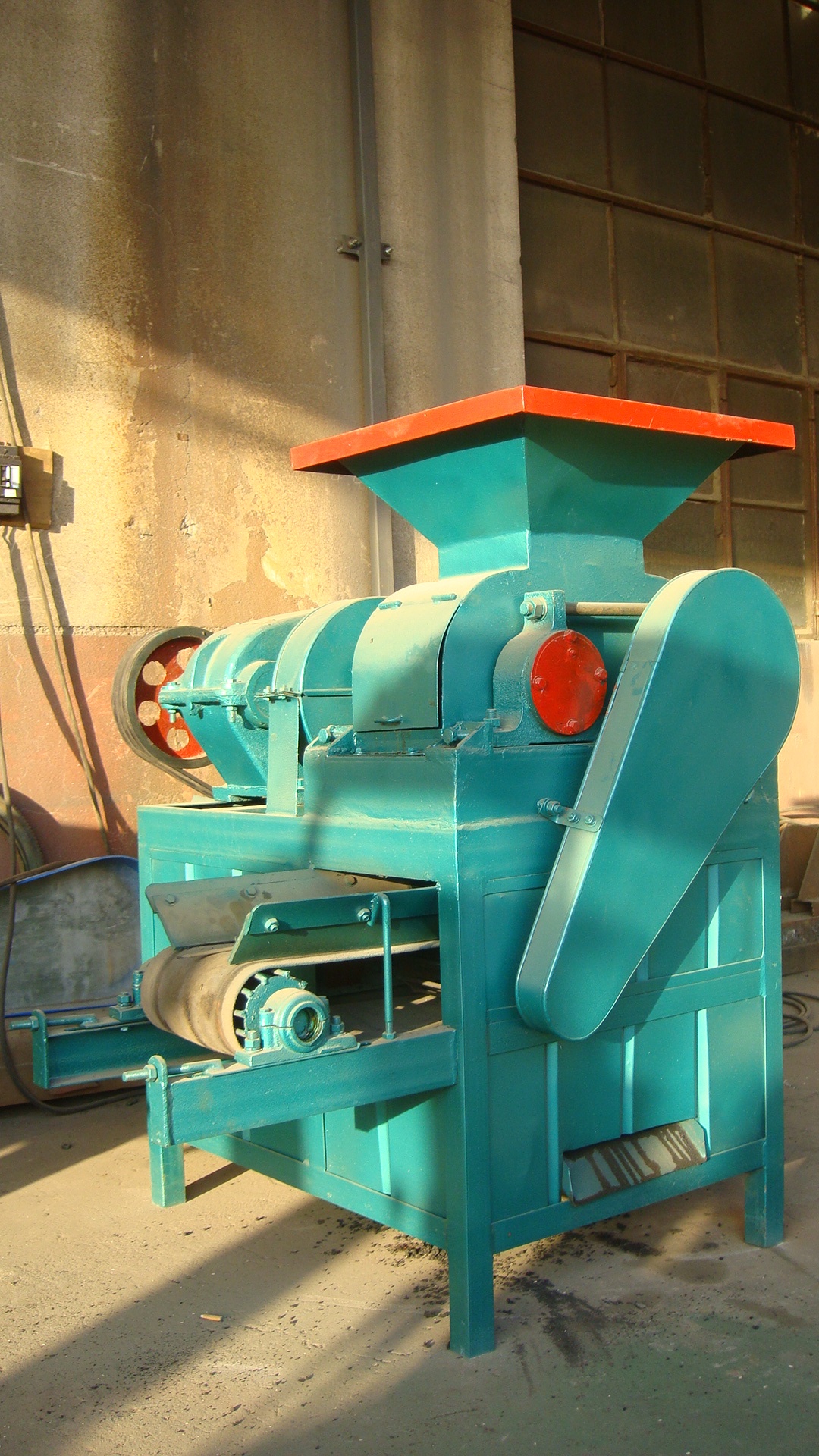

High production charcoal ball press briquetting machine

High production charcoal ball press machine factory price briquetting press for charcoal dust

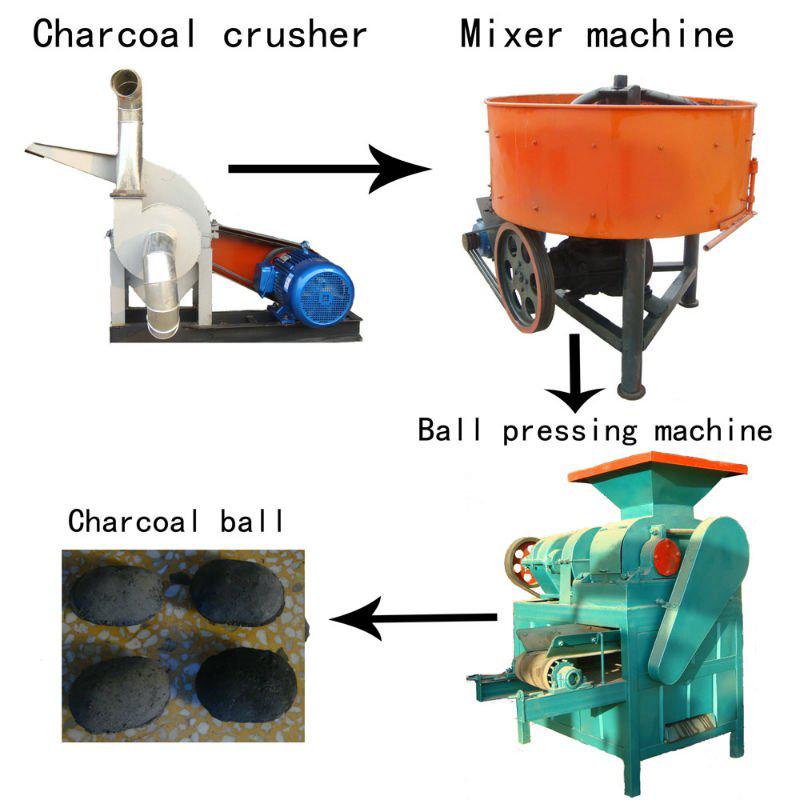

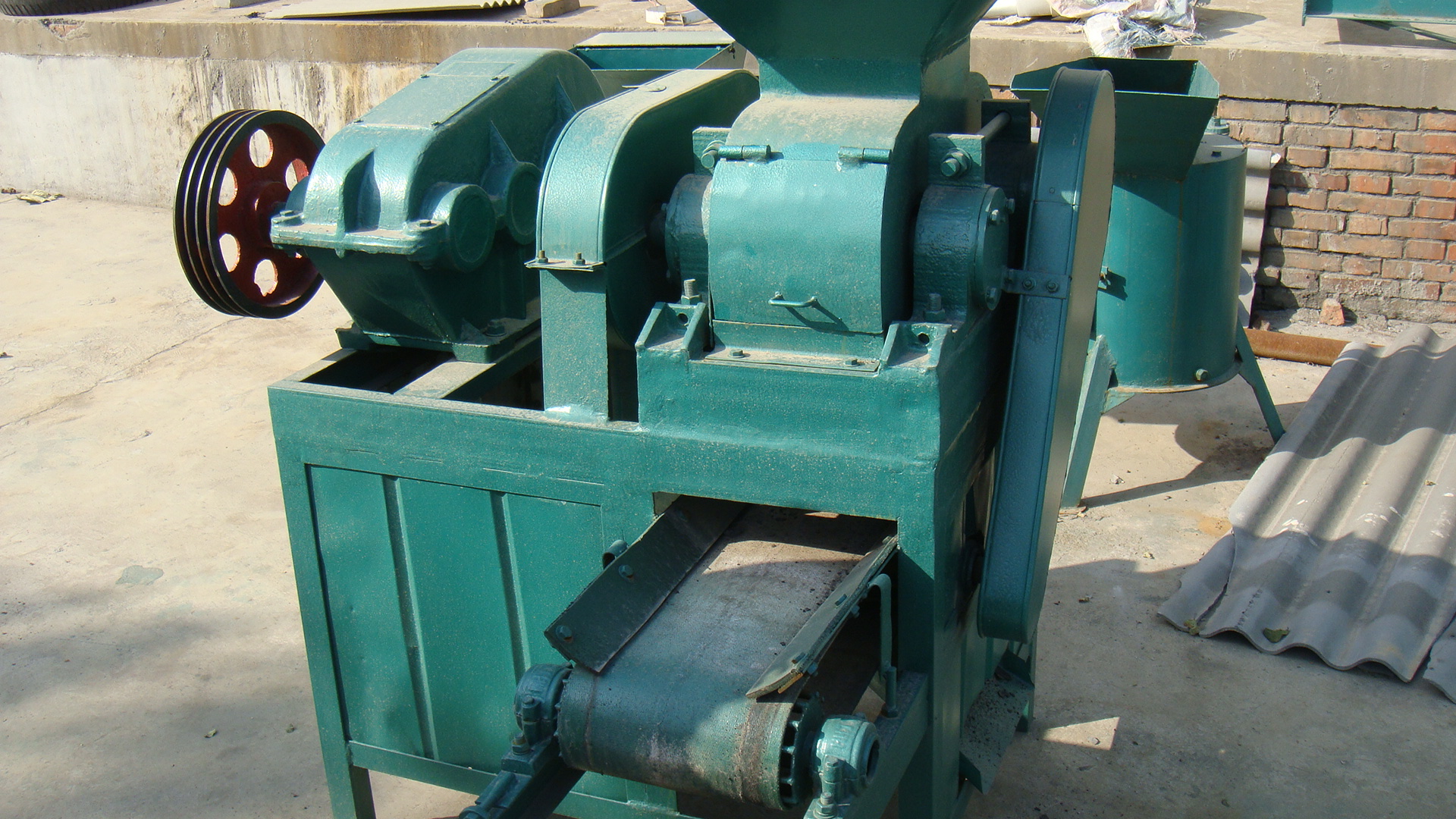

Ball press briquetting machine can press ore powder, metal powder, coal powder, coke powder and other materials into ball shape.The charcoal or coal briquettes can be different shapes by changing with special molds, such as oval, pillow, round, egg, ball, column and square. We can also customize the shape for our customers.

Final briquettes have features of high density, high strength, high hardness, high performance, and the main rollers adopt hard wear resistance materials, which improve roller’s service life greatly.

High production charcoal ball press machine factory price briquetting press for charcoal dust

1. Making briquettes of diverse coal fines, coke breeze, coal slurry and middling coal, the briquettes are used for industrial boilers and civil furnaces.

2. Making briquettes of fine materials of non-ferrous metal and ferrous metal mineral to re-smelting in metallurgy industry, such as laterite nickel ore, alum ore, manganese ore, furnace dust, steel slag, iron slurry, mineral waste residue, carbon black, copper powder, magnesium, alumina,iron ore concentrate, manganese ore, silicon manganese alloy materials and so on.

3. Making briquettes of desulfurized gypsum generated in thermo-eletric plants, which can be used for the cement production (using wet model briquette press for easy to de-mouding).

4. Making briquettes of coal dust in chemical and fertilizer industries, replacing lump coal for gas production, which save costs and increase economic benefits.

5. Making briquettes of coal dust to replace lump coal in lime factories, building material and chemical industry, it can save cost; making briquettes of coal dust in ceramics factories, glass factories and coal- gas generator, replacing lump coal to save cost.

6. Making briquettes of refractory materials in refractory industry.