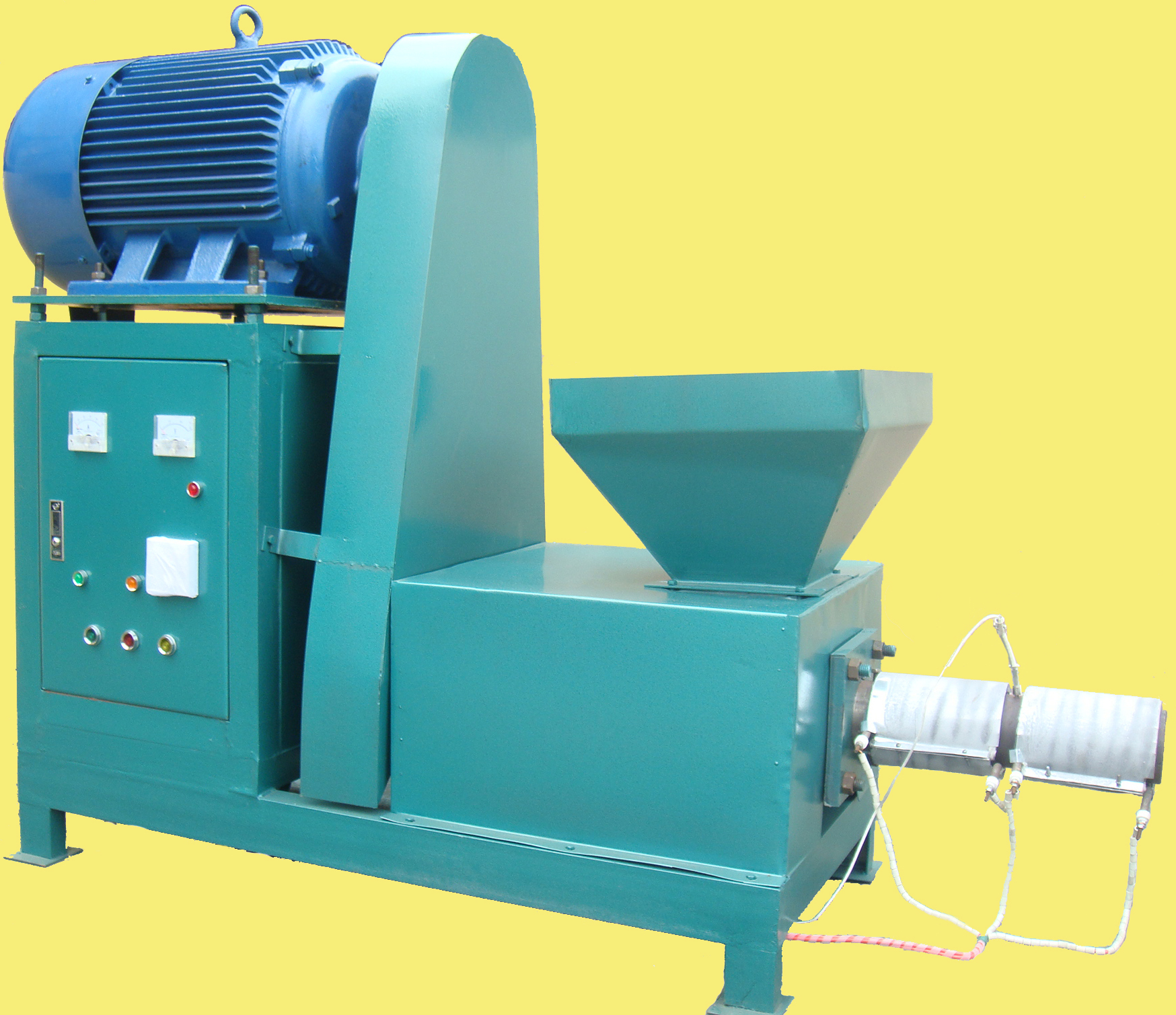

Factory Sale Wood Biomass Waste Sawdust Briquette Charcoal Making Machine

Factory Sale Wood Biomass Waste Sawdust Briquette Charcoal Making Machine

Applicable Industries: Hotels,Manufacturing Plant,Home Use, Energy & Mining

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Application: Produce fuel briquettes

Production Capacity: 98%, 300kg-5000kg/h

Voltage: Customization, 220V (voltage can be customized)

Weight: 700 KG

Raw material: Sugarcane, firewood, sawdust, rice husk

Spare parts: Screw propeller, heating ring

Function: Make Stick Shape Briquette

Briquette shape: Square, cube,hexagonal,cylinder

I. Introduction of Wood Biomass Waste Sawdust Briquette Charcoal Making Machine

Raw material: Biomass wastes, such as sawdust,rice husks,coffee husks,rice straw, wheat straw,etc.

Material required: Moisture 5%-12%,size3-5mm

If moisture>12% may need dryer,We have air flow dryer and drum dryer.

If material size >5mm will need hammer mill or wood crusher.

When begin to work,the heating circle heat the machine,then wood briqutte machine can press sawdust without any binder, sawdust pressed by high temperature and high pressure , then the screw press sawust forward,extrusion into a rod-shaped solid rod with center hole.

II. Working Principle of Wood Biomass Waste Sawdust Briquette Charcoal Making Machine

The use of the inherent characteristics of wood raw materials, the pressure of the screw through the high temperature softening of the biomass material, at high temperature and pressure, the wood raw materials in the lignin cellulose fiber combination to form a semi-finished products with a central hole.