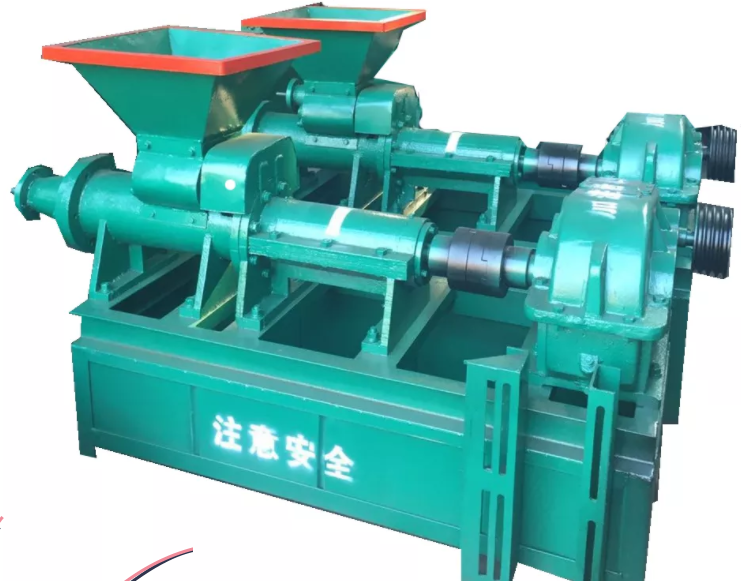

Coal stick extruder charcoal powder extruder machinery

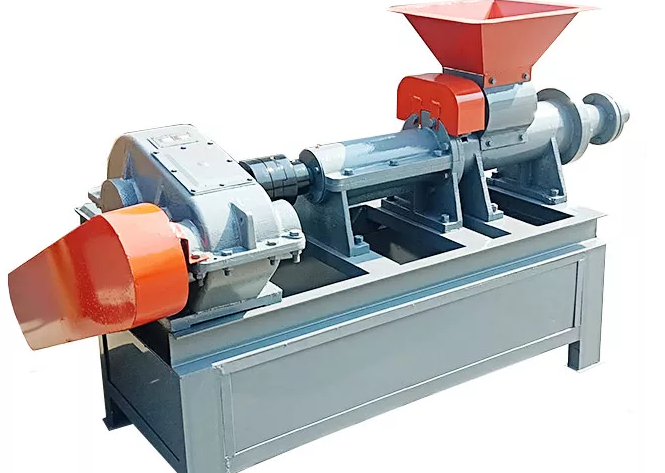

charcoal stick extruder machine is mainly used to use the screw extrusion principle to process charcoal or coal powder mixed with a certain proportion of liquid binder into different shapes and size of briquettes.

It can press cylinder shape/hexagon shape/cubic shape and other shapes by changing the mold

Coal stick extruder charcoal powder extruder machinery

1.The material is transferred to the conditioner by a screw feeder, then the conditioner can make different materials fully mixed.

2.The conditioner plays a key role in softening raw materials by utilizing water or steam.

3.After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning rollers in the chamber force the material through the holes of the die, thus pellets are formed.

4.After pelletizing, the length of the pellet can be cut according to different user’s request.

ADVANTAGES of the Coal stick extruder charcoal powder extruder machinery

1. CE certified ISO9001 Advanced technological design requiring less labor .

2. Potential for 24 hour continuous running.

3. Competitive price with good quality.

4. Low energy consumption and less manpower.

5. Durable spare parts KAF series good quality gear box.

6. Simple automated operation Stable and durable functionality.

7. Easily maintained Good quality brand bearing inside of the rollers