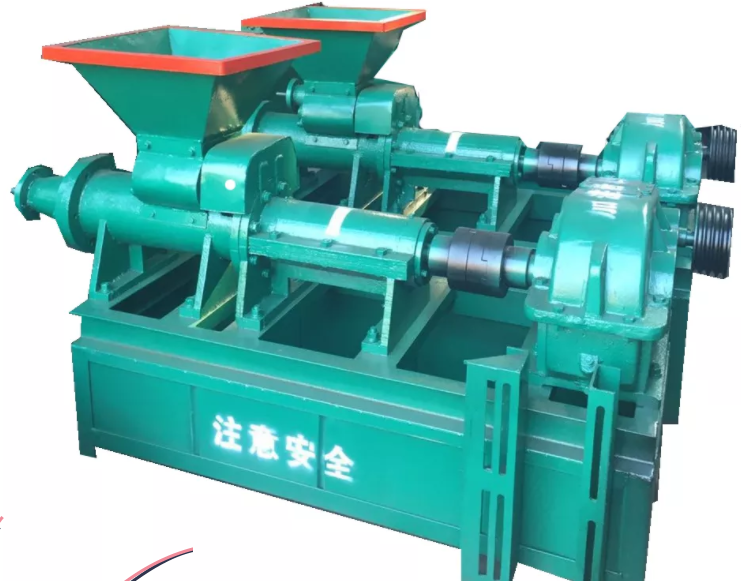

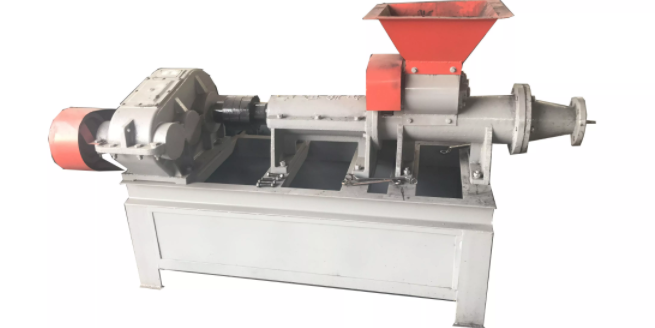

Charcoal Coal Briquette Extruder Equipment

Charcoal Coal Briquette Extruder Equipment

1.The material is transferred to the conditioner by a screw feeder, then the conditioner can make different materials fully mixed.

2.The conditioner plays a key role in softening raw materials by utilizing water or steam.

3.After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning rollers in the chamber force the material through the holes of the die, thus pellets are formed.

4.After pelletizing, the length of the pellet can be cut according to different user’s request.

Charcoal Coal Briquette Extruder Equipment Charcoal Coal Briquette Extruder Equipment

Charcoal Coal Briquette Extruder Equipment

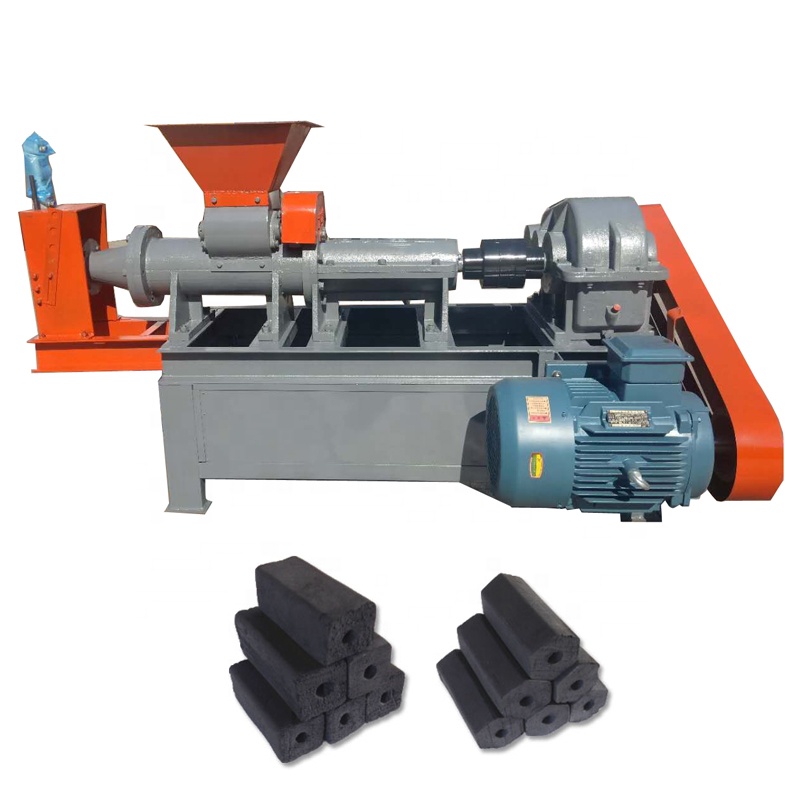

The Charcoal Coal Briquette Extruder Equipment hay biomass sawdust charcoal screw extruder briquette compression machine is a kind of briquette machine which can press the powder of coal, charcoal, carbon black and other materials into rods which has certain intensity.

2. The shape of rods can be round, six prismatic, square and so on. Also the rod shape can be customized.

3. The rods have large heating value, high economic benefit, The machine is widely used in chemical fertilizer factory, boiler and so on.

4. For the material, the particle size should be less than 5 mm adding material; the coal contains moisture content 12-14%