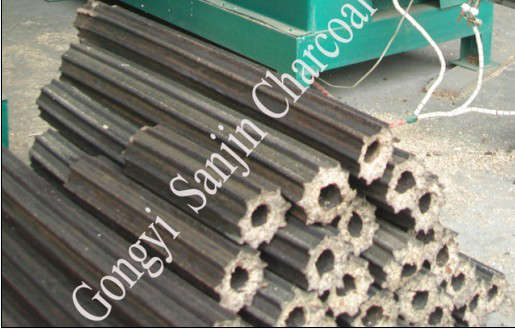

Biomass Briquette Production Press Charcoal Briquette Extruder

Biomass Briquette Production Press Charcoal Briquette Extruder

The final briquettes produced by this wood log briquette machine have a carbonized layer on the surface, but they are not completely carbonized. If you are planning to make charcoal briquettes, carbonization equipment is needed

Biomass Briquette Production Press Charcoal Briquette Extruder

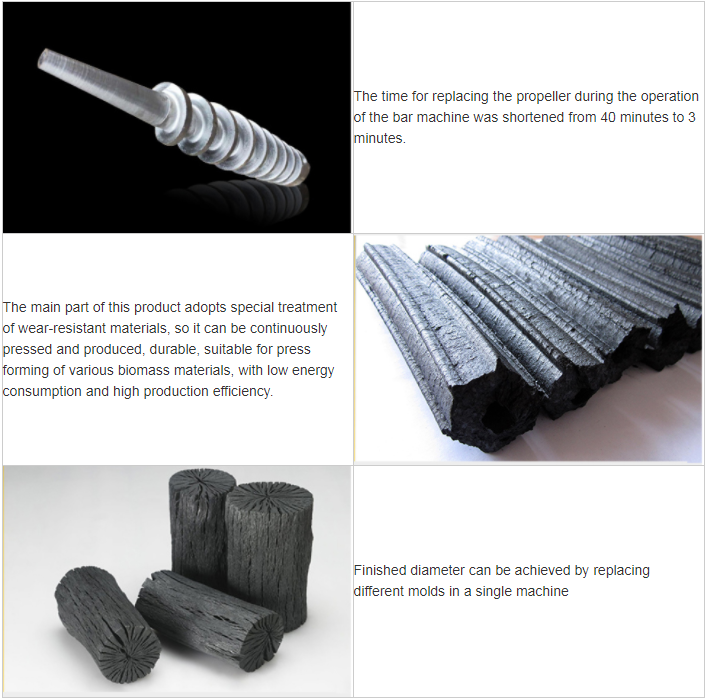

Long Life of Screw Shaft

We adopted a durable material (high hardness alloy steel) to make the shaft. We use a different process then what is normally used to make the screw shaft. Our screw shaft is manufactured with a milling machine which guarantees that the distance between every screw is the same, and the angle of every screw is the same.

Long Life of Inner Former

The Inner Former can be used for 1-2 years. The former is made from a whole steel bar through a water jet cutting system so that the inner face is smooth. Therefore, it’ll be easier to form and save energy. This is why the produced briquette is smooth. It consists of two parts, you need to change only the key part when it is worn.

Heating section

We adopted two heat collars which are made from thick copper wires and are ceramic inside.

Forming Hopper

An attractive feature on the forming hopper is that we added a movable plate on the bottom. It has two functions, one is you can clean it easily. The other is that you can discharge the inputted material when it is jammed.

Lubricating System

We have adopted a lubricating system for the gear box. In order to oil the gear box properly, it has an exhaust function to maintain consistent air pressure.