best selling wood sawdust briquette machine

best selling wood sawdust briquette machine

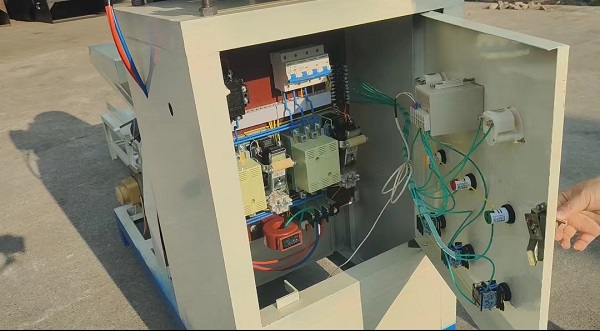

Voltage 380v,450v

Capacity 260-350kg/h

Motor power 18.5kw

Speed 40rpm

Raw material Peanut shells, bagasse,rice husk,sawdust,

Usage press the powder into briquettes

Moisture of raw material 8%-12%

Working type Screw Pushing

Package Wooden case

best selling wood sawdust briquette machine

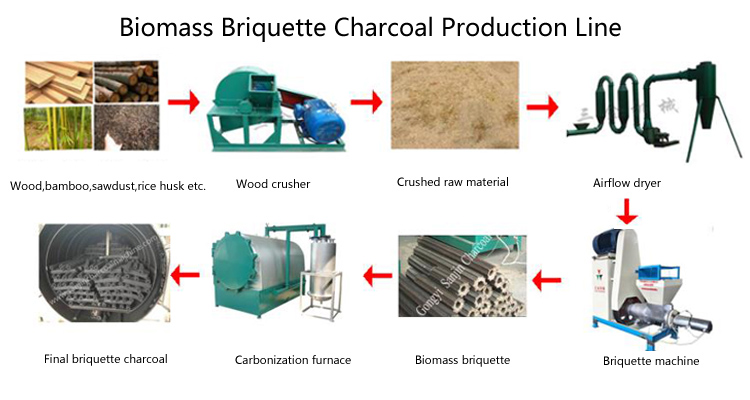

Step 1 Crushing

Crush the raw material(wheat straw, sunflower husk, coffee husk, soybean husk, rice husk, wood chips, sawdust, tae waste, cotton

stalk, paddy straw,peanut husk, and any other type of agro-forestry waste) into small pieces (size is about 3-5mm)

Step 2 Drying

Dry the material by the dryer machine or dried it in the sun, till the moisture is less than 8%- 12%;

Step 3 Forming shape

Put the dried material into feeding inlet of briquette machine by worker or by screw conveyor; Produce the briquette from the

dried material without any additive by the wood briquette machine;

The material is made into a wooden rod by high pressure molding at a high temperature of 300 to 350 degrees.

Step 4 carbonizing

After the sawdust briquette is formed, the shape is uniform and the humidity is right, so that it can be directly carbonized.