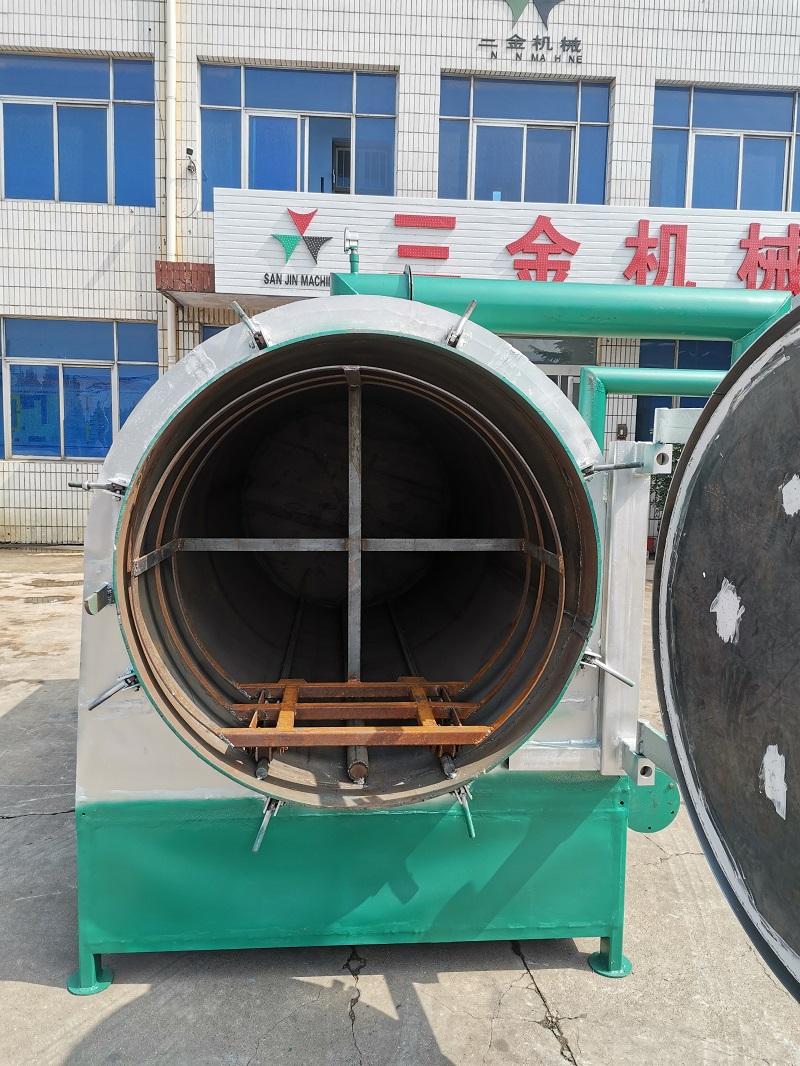

Bamboo Charcoal Carbonizer Furnace Oven

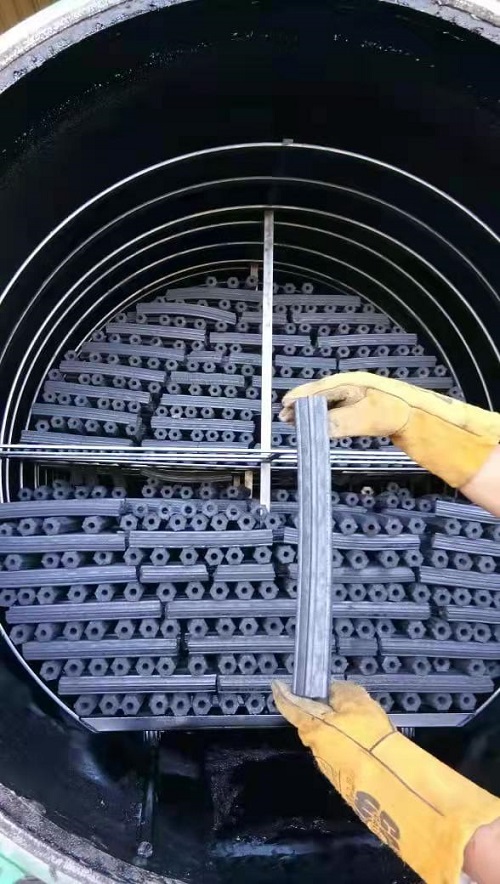

About Bamboo Horizontal Airflow Charcoal Carbonizer Furnace Oven, the raw material is verious: wood, wood branch, sawdust, coconut shell, rice husk, wood jute sticks coconut shell hookah bamboo sawdust, etc. Recycled wood tar, wood vinegar liquid. One ton charcoal can get 50kg of wood tar and wood vinegar liquid. Energy saving and environmental protection.

The whole charcoal carbonization furnace including: gas cleaner, fan, gas burners, furnace and other equipments

The charcoal carbonization furnace adopt dry distillation processing, fully utilization the carbon monoxide, methane, hydrogen and other combustible gases produced at carbonizating process, through gas cleaner system to separate wood tar, wood acid to collect gas, then as fuel to burn for furnace(temperature control around 600 ℃). There are four layers pipelines in the furnace, first and second layer pipeline for preheating and drying , the third layer pipeline for low-temperature carbonizating , the fourth layer pipeline for high-temperature carbonizating . There are pipes for dicharging exhaust steam at first and second layers. Third and fourth layer with gas recovery pipes for heating furnace to carbonization.